Model:WDLSZJ

With our own in-house design team and the ability to outsource to specialists when required, we can be reactive to the customer’s needs. We follow a continuous development plan and are always looking for ways to improve our products and develop new ones to satisfy customer demand.

Model:WDLSZJ

With our own in-house design team and the ability to outsource to specialists when required, we can be reactive to the customer’s needs. We follow a continuous development plan and are always looking for ways to improve our products and develop new ones to satisfy customer demand.

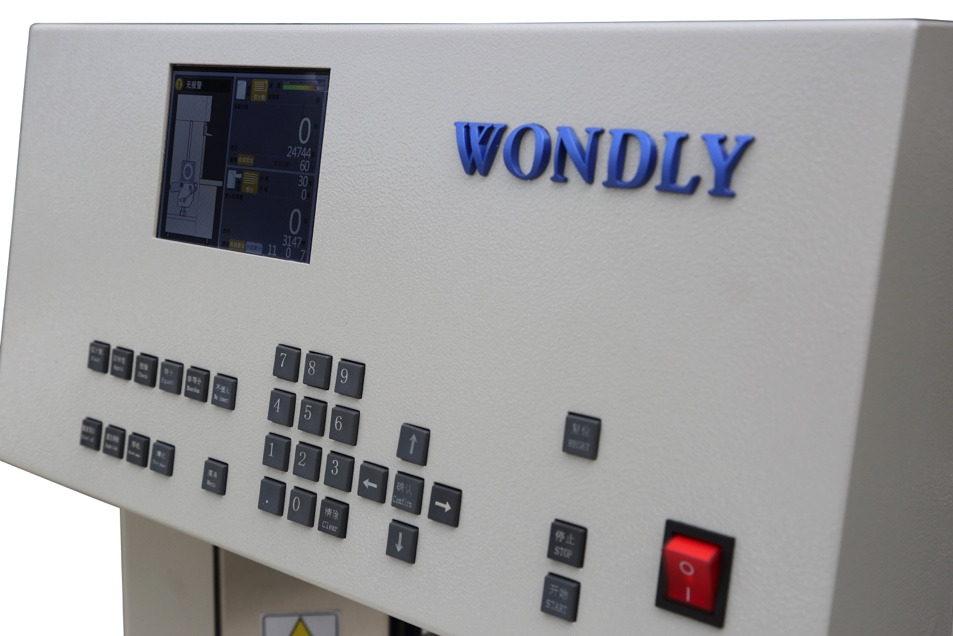

The structure of computer system and operation panel、7 inch touch + button dual function computer

Side structure of the paper sucking unit

Using Omron limit sensor

Japan Orion vacuum pump (Optional)

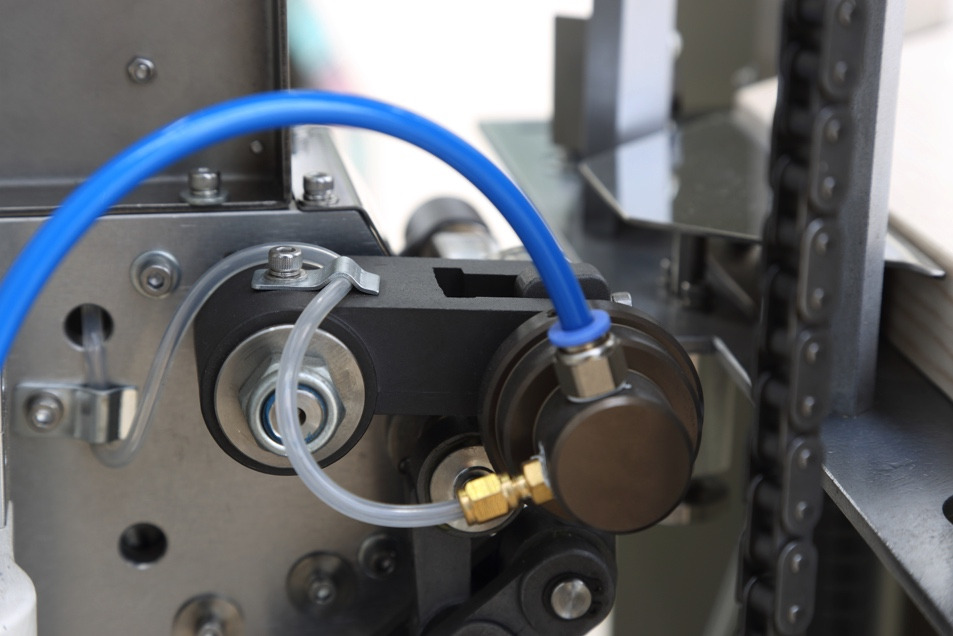

Front structure of the label cutting unit

Side view of the Japan Fuji motor unit

Using Japanese original NSK bearing

main parameters

| paper thickness range | 22~230kg(Carbon paper,offset printing paper, coated paper,etc.) |

| paper size | Min.100X150mm、Max 546X788mm |

| paper stacking height | 300mm(Max) |

| Power Supply/voltage | AC220±10V、50Hz |

| motor | 0.4KW |

| Collecting table width | 600X600mm |

| Collecting table width height | 760mm |

| machine size | 900(W)X1080(L)X1500(H) |

| machine weight | 230kg |

| label for paper in pile | Width 6mm、Length 100m |

| consumed power ; | 600W |

Main configuration

| America ARM Core CPU Frequency: |

400MHZ |

| SDRAM: | SAMSUNG DDR2,64MB |

| FLASH ROM: | SAMSUNG 64MB |

| Listepping moto | china |

| TFT: | Foxconn 7 Inch+ button dual function computer |

| KEYPAD: | OMRON |

| Paper Count Motor: | FUJI Servo Motor |

| Air Pump Motor: | china\korea |

| IF Sensor: | OMRON |

| Hall Sensor: | OMRON |

| Switch Power: | Taiwan Meanwell |

| Cable: | America TE |

Need Help With Finding The Right Technical Solution?